全國(guó)免費(fèi)咨詢熱線:17317317121(微信同號(hào))

工業(yè)領(lǐng)域使用空氣彈簧的發(fā)展前景

來(lái)源:上海松夏減震器有限公司????發(fā)布時(shí)間:2019-02-28 17:41

工業(yè)領(lǐng)域使用空氣彈簧的發(fā)展前景:空氣彈簧在工業(yè)機(jī)械上廣泛應(yīng)用于設(shè)備隔振,如在壓力機(jī)、空大氣的壓力縮機(jī)、離心思、振蕩運(yùn)送機(jī)、控制錘、鑄造機(jī)械和紡織機(jī)械、光學(xué)和激光儀器、集成電路、超精確機(jī)床等精確機(jī)械設(shè)備和精確測(cè)試設(shè)備上,在國(guó)外都得到了應(yīng)用。隨著社會(huì)的發(fā)展,很多人對(duì)生存的要求越來(lái)越高,由于這個(gè)工業(yè)空氣彈簧隔振技術(shù)會(huì)越來(lái)越多,其前面的景色非常廣大寬闊。

Industry USES air springs: the prospect of development of air spring is widely used in industrial machinery equipment vibration isolation, as in the press, empty atmospheric pressure indentation machine, from the mind, oscillation transporter, hammer, foundry machinery and textile machinery, optics and laser instrument, integrated circuits, ultra precision machine tools and other precision mechanical equipment and precise testing equipment, has been applied in foreign countries.With the development of society, many people have higher and higher requirements for survival. Due to the increasing number of industrial air-spring vibration isolation technologies, the landscape ahead is very broad.

在機(jī)械隔振中,空氣彈簧一樣覺(jué)得合適而運(yùn)用約束膜式和自由膜式結(jié)構(gòu)。空氣彈簧可應(yīng)用于各種機(jī)械裝置中起緩和沖突吸振、控制運(yùn)動(dòng)或增壓作用。與具有一樣功能的氣缸或其他彈性元件相比,空氣彈簧結(jié)構(gòu)簡(jiǎn)單、工作可靠,不需復(fù)雜的參量計(jì)算和結(jié)構(gòu)預(yù)設(shè),無(wú)嚴(yán)密封閉泄露問(wèn)題,運(yùn)用維護(hù)方便,且保存生命的年數(shù)較長(zhǎng)。若覺(jué)得合適而運(yùn)用空氣彈簧作為緩和沖突器,可下降加工成本并擔(dān)保加工精確度。物料傳遞中,料箱由振蕩器驅(qū)動(dòng)以使物料混合均勻,或使物料流動(dòng)以進(jìn)入了料箱中。振蕩會(huì)引起料箱支承部件疲勞乃至于破壞,由于這個(gè)必須覺(jué)得合適而運(yùn)用隔振裝置。

In mechanical vibration isolation, the air spring as appropriate and the use of constrained membrane and free membrane structure.Air springs can be used in a variety of mechanical devices to alleviate the impact of vibration absorption, control movement or pressure.Compared with the cylinder or other elastic elements with the same function, the air spring has simple structure, reliable operation, no complicated parameter calculation and structure preset, no tight seal leakage problem, easy operation and maintenance, and a long life.If the air spring is used as a conflict reliever, the processing cost can be reduced and the processing accuracy can be guaranteed.In the material transfer, the material box is driven by an oscillator to make the material mix evenly, or to make the material flow into the material box.Oscillations may cause fatigue and even damage to the supporting parts of the bin. Vibration isolation devices must be used as appropriate.

若運(yùn)用空氣彈簧則可供給較大的靈活性,調(diào)節(jié)彈簧的充氣量就可符合不同的工作負(fù)荷和高度要求,而不會(huì)影響隔振效果。在造紙、紡織等行業(yè)中,紙張或布匹在卷繞過(guò)程中需求以較高的速度繞過(guò)很多傳遞輥,由于這個(gè)傳遞過(guò)程中需求永遠(yuǎn)固定的張緊力,以免紙張或布匹松動(dòng)、扭曲或出現(xiàn)裂縫。在這種物質(zhì)情形下應(yīng)用空心卷輥—空氣彈簧組合結(jié)構(gòu),可供給永遠(yuǎn)固定的拉力。并且具有較強(qiáng)的承擔(dān)沖擊負(fù)荷的有經(jīng)驗(yàn),盡量照顧傳遞裝置和傳遞件不受損傷。空氣彈簧非常符合運(yùn)用于高壓力、小行程工況。在粘接工藝中,覺(jué)得合適而運(yùn)用空氣彈簧可供給均勻的壓力,擔(dān)保粘接品質(zhì)。現(xiàn)場(chǎng)運(yùn)用表明,空氣彈簧比鋼制壓縮彈簧的緩和沖突效果好,運(yùn)用保存生命的年數(shù)長(zhǎng),可提升設(shè)備效率和延長(zhǎng)設(shè)備運(yùn)用保存生命的年數(shù)。

If the use of air springs can provide greater flexibility, adjusting the spring air volume can meet the requirements of different workloads and heights, and will not affect the effect of vibration isolation.In the paper, textile and other industries, the paper or cloth in the winding process demand at a high speed around a lot of transfer roller, because the transmission process demand always fixed tension, so as to avoid loose paper or cloth, distortion or cracks.In the case of this substance, the hollow roller-air spring combination is used to provide a permanent fixed tension.And have strong experience of bearing shock load, try to take care of the transmission device and the transmission piece is not damaged.The air spring is suitable for high pressure and small stroke applications.In the bonding process, feel appropriate and the use of air springs can provide uniform pressure, guarantee bonding quality.Field application shows that the air spring has a better conflict mitigation effect than the steel compression spring, and the number of years of life saved by the use of the air spring is longer, which can improve the efficiency of the equipment and extend the number of years of life saved by the use of the equipment.

福建橡膠充氣囊寶馬多少錢(qián)柴油發(fā)電機(jī)組的主要噪聲源均為柴油機(jī)產(chǎn)生,包括排氣噪聲、機(jī)械噪聲和燃燒噪聲、冷卻風(fēng)扇和排風(fēng)噪聲、進(jìn)風(fēng)噪聲、發(fā)電機(jī)噪聲、地基振動(dòng)的傳遞所產(chǎn)生的…

天津橡膠密封氣囊充氣方法動(dòng)平衡檢測(cè)機(jī)發(fā)展迄今已經(jīng)有一百多年的歷史。直到上世紀(jì)末40年代,所有的平衡工序都是在采用純機(jī)械的平衡設(shè)備上進(jìn)行的。轉(zhuǎn)子的平衡轉(zhuǎn)速通常取振動(dòng)系統(tǒng)…

空氣彈簧百度文庫(kù)1、液壓傳動(dòng)是以液體作為橡膠橡膠空氣彈簧介質(zhì)來(lái)進(jìn)行能量傳遞的一種傳動(dòng)形式,通過(guò)能量轉(zhuǎn)換裝置,將原動(dòng)機(jī)的橡膠橡膠空氣彈簧能轉(zhuǎn)變?yōu)橐后w的壓力能,然后通過(guò)…

確定合理的橡膠空氣彈簧參數(shù) (1)橡膠空氣彈簧工作原理 橡膠空氣彈簧是一個(gè)內(nèi)部充以一定壓力氮?dú)饣蚩諝獾拿荛]容器,其基本功能是利用氣體的可壓縮性,隨著吸入壓力和排出壓…

甘肅橡膠水堵氣囊是什么材質(zhì)3、能夠有效隔離各類(lèi)臥式、立式水泵、風(fēng)機(jī)、空調(diào)機(jī)組、發(fā)電機(jī)組、管道、等動(dòng)力設(shè)備的振動(dòng),并保護(hù)及延長(zhǎng)其使用壽命上海松夏減震器有限公司致力于風(fēng)…

轉(zhuǎn)向架工業(yè)空氣彈簧企業(yè)互聯(lián)網(wǎng)時(shí)代的到來(lái),很多企業(yè)走電商之路,不少空氣彈簧企業(yè)也坐不住了,紛紛開(kāi)始“觸電”。然而,部分品牌“觸電”逐漸演變成形式主義。空氣彈簧企業(yè)需…

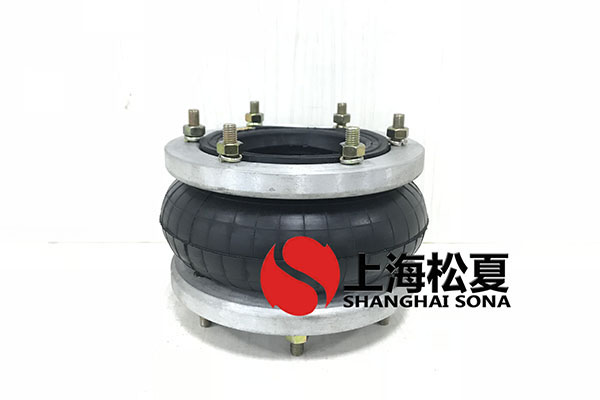

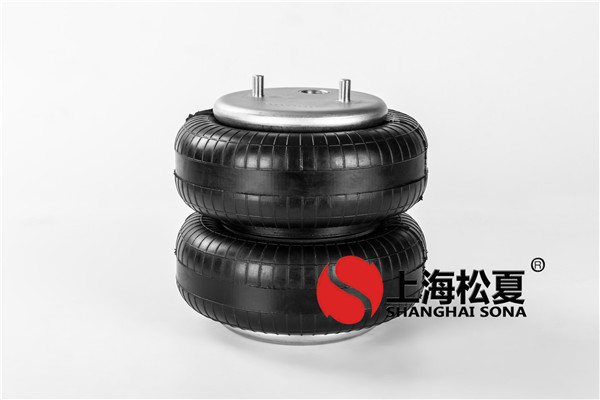

與工業(yè)領(lǐng)域使用空氣彈簧的發(fā)展前景相關(guān)的產(chǎn)品

-

HF150/076-2橡膠氣囊 調(diào)偏專用糾偏氣囊

HF150/076-2橡膠氣囊 調(diào)偏專用糾偏氣囊 橡膠氣囊產(chǎn)品介紹: 橡膠空氣彈簧是一種由橡膠、網(wǎng)線貼合成的曲形膠囊,俗稱橡膠氣囊、橡膠空氣彈簧、橡膠皮囊、橡膠氣胎、波紋氣胎、皮老..

-

HF215/120-1法蘭式橡膠空氣彈簧,糾偏氣囊

HF215/120-1法蘭式橡膠空氣彈簧,糾偏氣囊 橡膠空氣彈簧 產(chǎn)品介紹: 橡膠空氣彈簧是一種由橡膠、網(wǎng)線貼合成的曲形膠囊,俗稱橡膠氣囊、橡膠空氣彈簧、橡膠皮囊、橡膠氣胎、波紋氣..

-

S-300-2R臺(tái)式?jīng)_床氣囊ZF-300-2高速?zèng)_床空氣彈

ZF型自封式橡膠氣囊(沖床設(shè)備專用)介紹: 自封式,是因其無(wú)需外力自行密封而得名。如圖,用纖維層做補(bǔ)強(qiáng)處理的橡膠曲囊①在使用時(shí),將防止膨脹的鋼制(鍍鋅)腰環(huán)②嵌在其中。③蓋..

-

S-220-2RLED支架沖床空氣彈簧S-220-2R電動(dòng)沖床

ZF型自封式橡膠氣囊(沖床設(shè)備專用)介紹: 自封式,是因其無(wú)需外力自行密封而得名。如圖,用纖維層做補(bǔ)強(qiáng)處理的橡膠曲囊①在使用時(shí),將防止膨脹的鋼制(鍍鋅)腰環(huán)②嵌在其中。③蓋..

與工業(yè)領(lǐng)域使用空氣彈簧的發(fā)展前景相關(guān)的文章

- 碳化硅直線振動(dòng)篩安裝橡膠空氣彈簧 2024-06-25

- 圓型振動(dòng)篩安裝橡膠減震氣囊 2024-06-25

- 高速?zèng)_擊試驗(yàn)臺(tái)安裝箍環(huán)密封式氣囊 2024-06-25

- 壓力試驗(yàn)臺(tái)安裝橡膠空氣減震器 2024-06-25

- 電子探針顯微鏡安裝氣動(dòng)隔振器 2024-06-21

- 人防門(mén)專用振動(dòng)平臺(tái)安裝膜式減震器 2024-06-21

- 透射電子顯微鏡安裝膜式減震器 2024-06-21

- 實(shí)驗(yàn)橡膠減震平臺(tái)安裝薄膜式隔振器 2024-06-21

- 樹(shù)脂振動(dòng)篩分機(jī)用HF型空氣彈簧 2024-06-18

- 海上設(shè)備緩沖用HF型空氣彈簧 2024-06-18

全國(guó)免費(fèi)咨詢熱線:17317317121

上海松夏減震器有限公司 滬ICP備09066468號(hào)-13 網(wǎng)站地圖 站點(diǎn)地圖